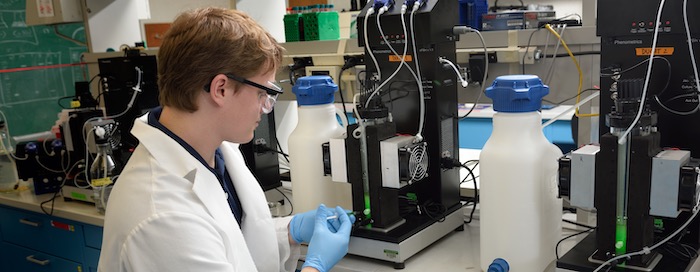

Environmental Photobioreactor

The Environmental Photobioreactor (ePBR) enables scientists to study algae under the same conditions found outdoors in the ponds, but in the much more efficient confines of the laboratory. Created and housed in the Kramer lab, each of the 50 ePBRs on site uses breakthrough technology to re-create the environmental conditions such as temperature, light intensity, and CO2. Researchers can choose from pre-programmed experiments, or they can quickly and easily design their own.

By Harley J Seeley Photography, 2014

Technical Specifications

The ePBR is specifically designed for the optimization and study of the growth of microalgae and cyanobacteria. It provides for a great number of algal growth conditions to be controlled, monitored, and recorded by computer, for accurate emulation of local environmental conditions, determination of optimal growth conditions, or both.

This technology allows for:

- The optimization of an individual strain under given production conditions, such as an outdoor raceway, or the selection of the best strain for use under existing environmental conditions.

- Virtually unlimited user-defined system control combinations. This is accomplished through Java scripting in Algal Command, a customized software package written specifically for the ePBR. The Java script of Algal Command is open-sourced, which allows advanced users to further customize system control.

- Up to 256 separate ePBR systems being controlled from a single laptop or desktop computer, simultaneously storing all of the data together. This allows for the most rapid diversification of experimental conditions possible, resulting in the highest-possible level of R & D or scientific study.

- The significant reduction in startup and operational costs while at the same time an increase in production yields and dramatically-reduced development times.

Controllable Variables

- 3000 μ-Einstein LED specially designed lighting system with conical vessel that accurately mimics BOTH raceway or production tube bioreactors (controllable from 0- 3000 in steps of 25 μ-Einsteins.)

- Fully programmable Diurnal Cycles: you set the length of sunlight day, and also the hour of peak sunlight.

- Fully programmable heating and cooling, linkable to the diurnal cycle; you can independently set the hour of peak heating (if different from peak sunlight).

- Active cooling and heating, from 5 – 50°C

- Algal Command Software provides for complete, simultaneous, integrated control of up to 256 bioreactors from a single computer, with collation of all data. All the reactors are linked together via Ethernet Hub.

- CO2 programmable and controlled from Algal Command.

- Mixing through active magnetic stirring and/or gas sparging.

- Active sparging of up to two gasses

- Temperature measurement

- True Turbidostatic measurement

- Field-configurable, fully autoclavable, low cost durable polycarbonate reactor vessel with as many inlets and outlets as you require

- 100% (+/- 10%) directly-proportional (by volume) up-scale to pond, raceway, or indoor reactor

- pH measured and controlled by Algal Command

- Custom-engineered Turbidostatic Pump allows for true turbidistatic operation; fully programmable and computer-controlled.